Clutch broken? - These symptoms indicate a defect in the clutch

Content

1. How the clutch works in the car

2. Defective clutch – these symptoms occur

The car’s clutch is subjected to great stress every time it is driven. It is hardly surprising that the wearing part will break down at some point. In our guide, you can find out what symptoms occur when the clutch is broken and when it is advisable to go to the workshop. We also tell you what you should keep in mind when driving to avoid damage to the clutch.

How the clutch works in the car

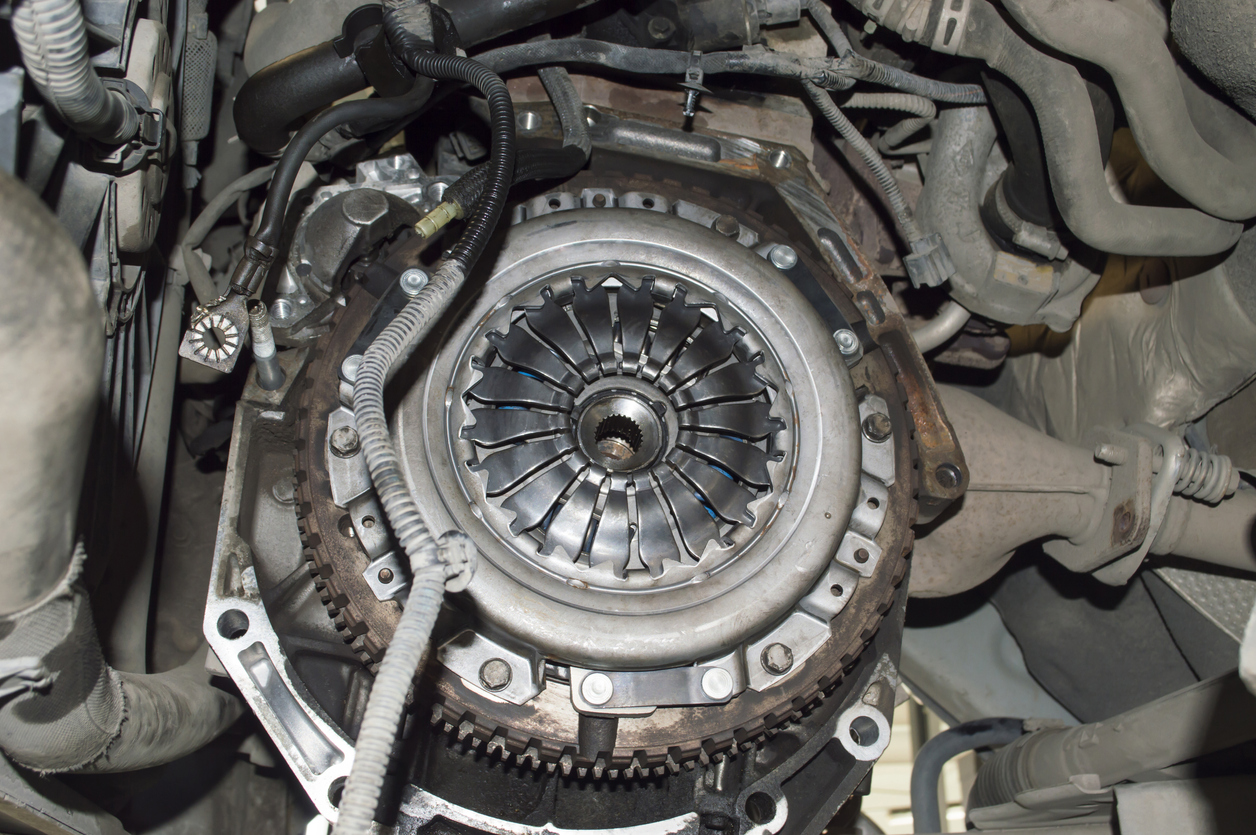

The clutch in a car is the link between the engine and the gearbox. When the clutch is closed, a clutch disc is pressed against the engine flywheel by the pressure of a diaphragm spring and via the clutch pressure plate. When the clutch pedal is depressed, the clutch opens and interrupts the transmission of power between the two components. Only then is it possible to change gear and start the car.

Operation of the clutch

The method of operating the clutch may differ depending on the vehicle. It is often operated by a clutch cable that transmits power from the clutch pedal to the clutch mechanism. Modern cars often have a hydraulically operated clutch, and some models also have an electronic actuator.

Clutch on manual transmission is a classic wearing part

In vehicles with a manual gearbox, the clutch is subject to constant wear. The driver has to use the clutch every time he changes gear, and starting off with a manual gearstick also requires stepping on the clutch pedal. This means that the material on the clutch lining wears out constantly every time the driver shifts into a gear and every time the vehicle starts off.

Coupling service life – how long do couplings last?

Normally, clutches in cars last a very long time. As a rule, the component only needs to be replaced after well over 100,000 kilometres of mileage. However, various factors can promote wear, so that clutch damage occurs sooner. In this case, it is often unavoidable to have the clutch replaced in the workshop.

Defective clutch – these symptoms occur

If the clutch is broken, various symptoms can indicate the defect. A worn clutch lining often manifests itself through the so-called slipping of the clutch. Due to wear, the frictional connection between the engine and the gearbox is no longer established correctly. The engine speed increases without the vehicle accelerating further.

- Clutch slips

- Engine howls loudly

- Jerking when starting and accelerating

- Noises when clutching or shifting gears

- Gear cannot be engaged

- Clutch pedal is sluggish

- Fuel consumption is increased

- Smell of burnt coating

Defective clutch – further signs of clutch damage

Depending on the type of defect, other symptoms may also occur when the clutch is broken. These include jerking when starting or accelerating. Unusual noises when clutching and changing gears can also indicate a defective clutch. Such signs can appear when the clutch no longer separates the engine and transmission properly.

Unusual smell or no gear

In some cases, the engine consumes more fuel if the clutch is defective. An unpleasant burnt smell can also be a sign of a defective clutch. Depending on which parts of the clutch are broken, other problems can occur. In the worst case, it is no longer possible to engage a gear, or the clutch pedal is sluggish.

Typical causes – this is why the clutch is defective

If the clutch is broken, there are various possible causes for the defect. On the one hand, all parts of the clutch wear out over time. This includes above all the lining on the clutch disc, which is stressed with every gear change. However, the use of the vehicle and the driving style of the driver also have an influence on the service life of the clutch.

- Wear due to high mileage

- Driving with heavy loads or trailers

- Driving in stop-go traffic

- Driving style is sporty

- Driver does not fully depress the clutch pedal

- Foot rests on the clutch pedal while driving

- Depressing the clutch pedal at traffic lights

- Slipping the clutch

- Starting with high engine speed

Driving style influences the wear of the clutch

Often the clutch breaks down or wears out prematurely because drivers do not operate a car with a clutch and manual transmission properly. For example, components such as the clutch disc wear excessively if the clutch pedal is not fully depressed. A sporty driving style can also be the cause of heavy wear.

Clutch broken due to bad habits

The driver’s foot should not rest on the clutch pedal while driving so that the clutch is always fully closed. Also, the pedal should not be held down steadily at traffic lights instead of taking the car out of gear. Frequent and heavy acceleration or so-called cavalier starts can also cause the clutch to break down.

Wear due to load or stop and go traffic

In addition to the individual driving style, the respective use of the vehicle can also lead to premature clutch damage. For example, the components of the clutch are subjected to greater stress when a car is moved with a heavy load. The same applies when operating the car with a trailer. Stop and go traffic in the morning can also promote clutch wear and cause defects due to frequent starting.

Change defective clutch

If there are first signs of a broken clutch, it should be tested and replaced if necessary. Although the clutch has no direct influence on driving safety, it should be replaced promptly. Otherwise, further problems could occur at any time, or the vehicle could unexpectedly come to a standstill with clutch damage.

Procedure for changing the coupling

If the engine and gearbox are installed transversely, the approach is different from that for an engine installed longitudinally. As a rule, however, the engine and transmission must always be separated. Since this is not easy, the repair is usually carried out in the workshop. Only experienced and skilled car mechanics carry out repairs to the clutch themselves.

Replacing the clutch on the rear-wheel drive

- Test the clutch: Before starting the repair, make sure that the clutch is defective. To do this, the car can be subjected to a short test. Whether the clutch is slipping is sometimes tested by pulling the handbrake and letting the clutch out. If the clutch is still OK, the engine stops.

- Prepare for repair: To carry out repairs on the clutch, a lifting platform is often helpful. After lifting the car, it is often necessary to loosen parts of the panelling. This may be necessary to get to the transmission block or the cardan shaft more easily.

- Pull off the gearbox: In order to be able to remove the gearbox block from the engine, some brackets and screw connections must first be loosened. Depending on the model, first remove the cardan shaft or unhook the gearshift linkage. In the meantime, the transmission unit can be supported with a transmission jack. Once everything is done, the gearbox unit can be detached.

- Change the clutch: After pulling the gearbox off the engine block, the gearbox bell releases the clutch so that the clutch can be changed. The clutch is then removed and inspected. It is often a good idea to install a complete clutch kit that includes all components as well as the clutch disc.

- Installing the clutch: The new clutch or clutch kit is installed next in place of the defective components. This often requires special tools, such as a centring pin for clutch assembly. The transmission unit can then be put back on and the repair completed. After all the components have been fitted, a test is carried out.

Top guides

- Injection system in the car explained simply - parts and function of the injection...

- Maintenance and repair of electric cars: what can your normal garage do?

- Increasing performance with chip tuning: benefits, risks and tips

- Guide: Computer systems and software in your car

- Which electric car parts need repair or replacement most often?

- What is a solid-state battery for electric cars?

- All about engine sensors: from combustion engines to electric cars

- Increase the range of an electric car: How every electric car gets further

- Electric car battery life: How to extend the life of the battery

- What is the compression of a car engine?

- This is the cubic capacity of a car engine

- Internal combustion engine valves: function, defects and repair

- Core components of the internal combustion engine - parts and functions

- Engine lubrication in cars: components, function and defects

- The environmental impact of manufacturing new car parts

- All about pollutant classes and their role in environmental protection

- Engine overhaul: What is an engine overhaul and how much does it cost?

- OEM car parts manufacturing: the key components of the sector

- Understanding engine power - insight into the technology of the car engine

- The steering system of the car - structure and operation

- The car's braking system - structure, parts and function

- Engine types in the car: V-engine, in-line engine and boxer engine explained

- 8 tips before buying a used electric car

- Distinguish OEM parts, aftermarket and counterfeit car parts

- The EPC indicator light is on or flashing: What to do?

- Master brake cylinder: function, defect detection and repair

- OEM car parts for hybrid and electric cars

- Used youngtimer and classic car parts - the best tips

- Cruise control: Function and repair of the cruise control system in the car

- Exhaust system: Everything you need to know about parts and function of the exhaus...

- Locking system: security and reliable locking on the car

- The engine's air intake system - parts, function and replacement

- Brake caliper defective? How to replace it yourself

- Fuel system: parts of the fuel supply from the tank to the cylinder

- Air conditioning system: function and components of your car air conditioning syst...

- The clutch: structure and function explained simply

- Detecting and replacing a defective fuel pump

- Surprised? So many pumps work in your car

- The most common causes of a defective electric car

- The 6 most important safety components of your car

- Identify and repair a defective starter in a flash

- 5 common chassis problems and how to fix them

- 10 unknown car parts that many drivers do not know about

- Engine cooling: function and important components of the cooling system

- Differences between petrol and diesel engines

- All-wheel drive: How the mechanics and components of all-wheel drive work

- Engine control unit car: Everything about components and functioning

- Defective engine control unit: causes, symptoms and repair

- HP vs. torque: What is the difference between power and torque?

- EV motors basics: How are they built, how they work and differ from combustion eng...

- The chassis: overview and function of all suspension components

- Used electric car parts: What to look out for

- The importance of the chassis number when buying used car parts

- ABS pump defective? Function, repair and replacement

- Injection nozzle defective? Diagnosis, cleaning and changing the injection nozzles

- Alternator defective? What symptoms occur and when to change the component

- Water pump defective? Symptoms and how to repair or change it

- Steering gear defective? What are the symptoms and when should the component be re...

- Lambda sensor defective? What are the symptoms and can I clean the sensor?

- Defective air conditioning compressor - what are the symptoms and when should the ...

- Intake manifold defective? Replace gasket or clean manifold?

- Exhaust manifold leaking? Symptoms of a defective exhaust manifold or gasket and w...

- Turbocharger defective? Repair or change?

- Servo pump defective? What symptoms occur and when you should change the part

- Clutch broken? - These symptoms indicate a defect in the clutch

- Common problems and repair of defective drive shafts

- Causes of engine noise and what to do about it?

- What can car diagnostic devices do and do I need an OBD scanner?

- When and how to replace brake discs and brake pads

- Brake warning lamp lights up - causes and what to do?

- EGR valve defective: Avoid engine problems and clean EGR valve

- Improve fuel consumption: How your car uses less fuel

- Squeaking brakes: Why brakes squeak and how to get rid of it

- Safely jacking up a car: How to jack up a car using a jack and jack stands

- How a defect in the muffler becomes noticeable and how it is replaced

- E-car motor: These electric car parts you can replace yourself

- Engine overheated: What you should do if the engine overheats

- Engine check lamp lights up: What you should do as a motorist

- The engine code: What does the code mean and where can I find it on the car?

- Tools for car repair: These 10 tools you should own

- Car repair mistakes: These are the 7 most common car repair mistakes

- The gearbox code: What does the code mean and where can it be found on the gearbox...

- Used parts: How to check the quality of used car parts

- Vehicle transmission: What is the difference between manual and automatic transmis...

- Mileage: This is how mileage affects used spare parts

- Car recycling: What happens to the car when it is recycled?

- OEM original parts or aftermarket: these are the differences

- Advantages and disadvantages of new and used car parts

- Starting problems? Top 9 reasons why your car does not start

- What’s that smell from my car? Top causes and cures

- Advantages of shopping scrap car parts online vs. going to the local breaker yards...

- 10 most frequently purchased car parts from car breakers/junkyard

- Important car parts and their function

- Common car engine problems: Diagnosing, Troubleshooting and Fixes

- Best tips for setting up your own home car workshop

- 7 Car parts replacements and repair tasks you should not do yourself

- DIY Car Maintenance and Repair Tasks

- Guide: How to Maintain and Protect Your Car Engine

- Best practices for Engine Rebuild

- Common Causes of Rear Differential Noise, troubleshooting, and how fix it

- Common Causes of power steering noise and how fix it

- Your Guide to Car Engine Components and Functions

- Licence plate and VIN information

- Top 10 of the most popular brands in second-hand autoparts

- France is just so cool