Injection nozzle defective? Diagnosis, cleaning and changing the injection nozzles

Content

1. Function of the injection nozzle in the engine

2. Signs of faulty injection nozzles at a glance

The injection nozzle is one of the most important components of modern injection systems. In earlier times, engines still had a carburettor or intake manifold injection, which provided an ignitable mixture of air and fuel. In modern fuel-injected internal combustion engines, on the other hand, the fuel is injected directly into the cylinders at high pressure. Find out now which symptoms occur in the event of a defect, how costs for subsequent repairs can be avoided, and when it is worth changing the injection nozzles.

Function of the injection nozzle in the engine

As part of the direct injection system, the injection nozzle ensures that the fuel always enters the combustion chamber in a finely atomised form and can be ideally ignited. The right amount of fuel is always injected into the cylinder via the injection nozzle. Depending on the engine design, different types of injection nozzles are used. Diesel engines have injection nozzles or injectors, petrol engines also have injection valves.

Signs of faulty injection nozzles at a glance

If an injector is defective or working incorrectly, typical symptoms often indicate this. Since the fuel is only inadequately atomised via defective injectors, signs such as rough engine running are often evident. The engine may also start badly or stop while driving if the injection quantity is not correct.

- Engine runs out of round

- Starting problems

- Fuel consumption is increased

- Vehicle jerks and goes out

- Exhaust gases are discoloured blue or grey

- Car smells of fuel

- Engine knocks or sounds unusual

- Values in the exhaust emission test are poor

- Engine indicator light comes on

Often a car with a faulty injection valve or injector is noticeable due to increased fuel consumption. The check engine light may also illuminate. Unusually blue or grey exhaust gases and a smell of fuel can also indicate defective injectors. Sometimes cars with defective injection nozzles also fail the emissions test due to poor exhaust emission values.

The symptoms should always be observed

If the first signs of defective injectors appear, the car should be taken to a workshop as soon as possible. With diesel engines, it is not uncommon for too much diesel to be injected due to a faulty injector. This in turn can lead to corking, for example in the area of the valves. A defective and dripping injector can cause damage to the piston. In addition to damage to the interior of the engine, too much injected fuel can also damage components such as the catalytic converter.

Causes of problems with the injection nozzles

If an injection nozzle is defective, there are various possible causes. Often, a blockage of the fine nozzles occurs due to contamination. Diesel or petrol of low quality or contamination in the fuel system can be responsible for this. The use of unapproved and unsuitable additives can also lead to problems with the injection nozzles. Often, increasing wear on injection nozzles or injectors occurs with high mileage. Then a change of the injection nozzle or injector is often unavoidable. But a defective fuel pump can also cause broken injectors due to metal chips.

Avoiding faults on the injection nozzle

A faulty injector or a defective injection valve can quickly lead to problems and consequential damage. The costs for subsequent repairs can be easily saved if the car is regularly serviced in the workshop. During a detailed maintenance or a special engine check, every nozzle and injector is examined. It is often possible to clean dirty components, otherwise they are replaced with new parts.

Care and maintenance of the injectors

Vehicles that are regularly serviced in the workshop are less prone to defects. Complications such as defective injection nozzles are also detected much earlier during maintenance. This in turn saves costs for expensive follow-up repairs. Defects in the injection system can be avoided with simple measures.

- Have the car serviced regularly at the workshop

- Refuel vehicle only with designated fuels

- Fill up with good quality petrol or diesel

- Use additives only if approved by the vehicle manufacturer

- Do not delay repair and replacement of parts

Regular maintenance of the engine and cleaning of the injection nozzles prolongs the life of the units. However, the symptoms do not always have to be caused by faulty injection nozzles. A defect in the ignition or other defective parts in the injection system can also be responsible for poor engine running, for example. Therefore, inspection, cleaning and replacement of the components are a matter for the specialist.

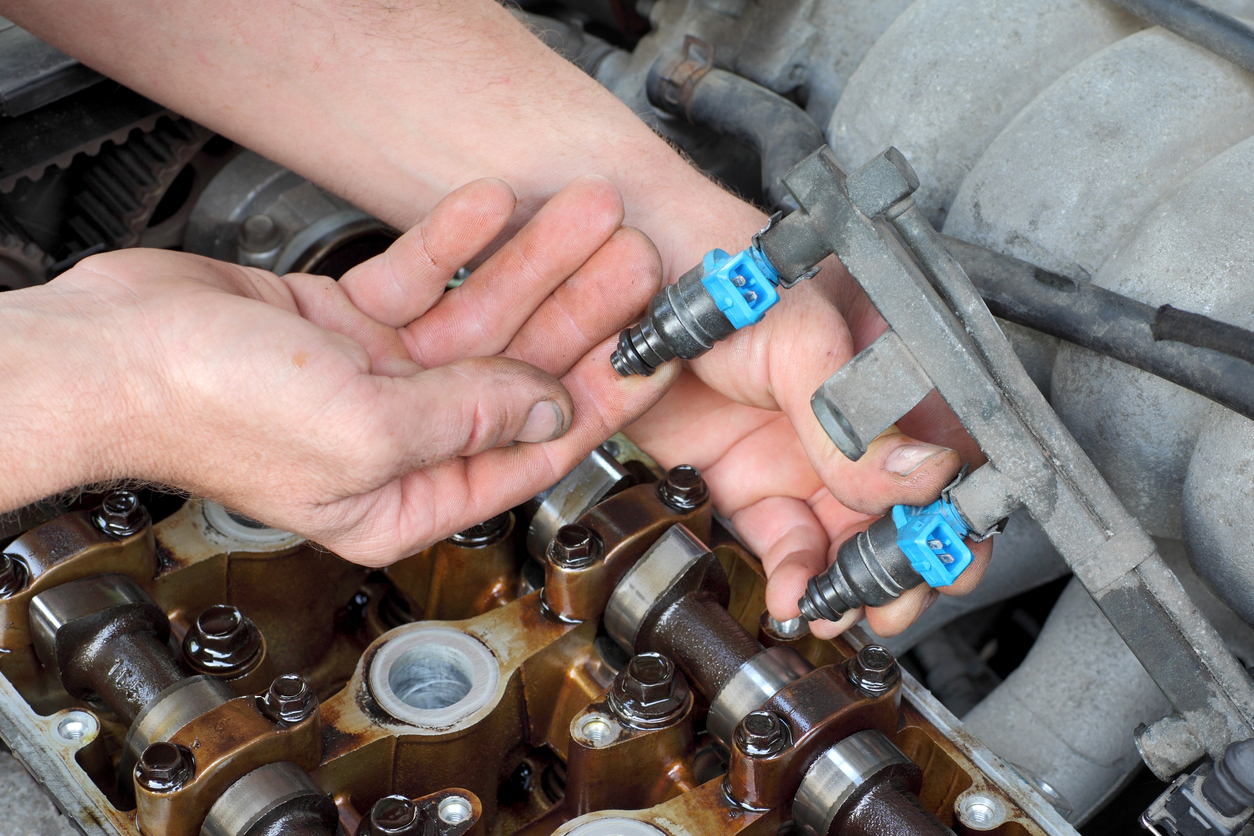

Repair and replacement of the injection nozzles in the workshop

For the repair, the injection nozzle must be removed and disassembled. The individual parts can then be inspected and replaced with spare parts in the event of a defect. As the complexity of the injection systems increases, the repair of the components also becomes more complicated. Only specialised companies offer the repair of components such as injectors and injection nozzles. Depending on the cost of the repair or a new injection nozzle, it may also be worthwhile to exchange them for new parts. Make an appointment with your workshop to have the engine and injectors inspected.

Top guides

- Injection system in the car explained simply - parts and function of the injection...

- Maintenance and repair of electric cars: what can your normal garage do?

- Increasing performance with chip tuning: benefits, risks and tips

- Guide: Computer systems and software in your car

- Which electric car parts need repair or replacement most often?

- What is a solid-state battery for electric cars?

- All about engine sensors: from combustion engines to electric cars

- Increase the range of an electric car: How every electric car gets further

- Electric car battery life: How to extend the life of the battery

- What is the compression of a car engine?

- This is the cubic capacity of a car engine

- Internal combustion engine valves: function, defects and repair

- Core components of the internal combustion engine - parts and functions

- Engine lubrication in cars: components, function and defects

- The environmental impact of manufacturing new car parts

- All about pollutant classes and their role in environmental protection

- Engine overhaul: What is an engine overhaul and how much does it cost?

- OEM car parts manufacturing: the key components of the sector

- Understanding engine power - insight into the technology of the car engine

- The steering system of the car - structure and operation

- The car's braking system - structure, parts and function

- Engine types in the car: V-engine, in-line engine and boxer engine explained

- 8 tips before buying a used electric car

- Distinguish OEM parts, aftermarket and counterfeit car parts

- The EPC indicator light is on or flashing: What to do?

- Master brake cylinder: function, defect detection and repair

- OEM car parts for hybrid and electric cars

- Used youngtimer and classic car parts - the best tips

- Cruise control: Function and repair of the cruise control system in the car

- Exhaust system: Everything you need to know about parts and function of the exhaus...

- Locking system: security and reliable locking on the car

- The engine's air intake system - parts, function and replacement

- Brake caliper defective? How to replace it yourself

- Fuel system: parts of the fuel supply from the tank to the cylinder

- Air conditioning system: function and components of your car air conditioning syst...

- The clutch: structure and function explained simply

- Detecting and replacing a defective fuel pump

- Surprised? So many pumps work in your car

- The most common causes of a defective electric car

- The 6 most important safety components of your car

- Identify and repair a defective starter in a flash

- 5 common chassis problems and how to fix them

- 10 unknown car parts that many drivers do not know about

- Engine cooling: function and important components of the cooling system

- Differences between petrol and diesel engines

- All-wheel drive: How the mechanics and components of all-wheel drive work

- Engine control unit car: Everything about components and functioning

- Defective engine control unit: causes, symptoms and repair

- HP vs. torque: What is the difference between power and torque?

- EV motors basics: How are they built, how they work and differ from combustion eng...

- The chassis: overview and function of all suspension components

- Used electric car parts: What to look out for

- The importance of the chassis number when buying used car parts

- ABS pump defective? Function, repair and replacement

- Injection nozzle defective? Diagnosis, cleaning and changing the injection nozzles

- Alternator defective? What symptoms occur and when to change the component

- Water pump defective? Symptoms and how to repair or change it

- Steering gear defective? What are the symptoms and when should the component be re...

- Lambda sensor defective? What are the symptoms and can I clean the sensor?

- Defective air conditioning compressor - what are the symptoms and when should the ...

- Intake manifold defective? Replace gasket or clean manifold?

- Exhaust manifold leaking? Symptoms of a defective exhaust manifold or gasket and w...

- Turbocharger defective? Repair or change?

- Servo pump defective? What symptoms occur and when you should change the part

- Clutch broken? - These symptoms indicate a defect in the clutch

- Common problems and repair of defective drive shafts

- Causes of engine noise and what to do about it?

- What can car diagnostic devices do and do I need an OBD scanner?

- When and how to replace brake discs and brake pads

- Brake warning lamp lights up - causes and what to do?

- EGR valve defective: Avoid engine problems and clean EGR valve

- Improve fuel consumption: How your car uses less fuel

- Squeaking brakes: Why brakes squeak and how to get rid of it

- Safely jacking up a car: How to jack up a car using a jack and jack stands

- How a defect in the muffler becomes noticeable and how it is replaced

- E-car motor: These electric car parts you can replace yourself

- Engine overheated: What you should do if the engine overheats

- Engine check lamp lights up: What you should do as a motorist

- The engine code: What does the code mean and where can I find it on the car?

- Tools for car repair: These 10 tools you should own

- Car repair mistakes: These are the 7 most common car repair mistakes

- The gearbox code: What does the code mean and where can it be found on the gearbox...

- Used parts: How to check the quality of used car parts

- Vehicle transmission: What is the difference between manual and automatic transmis...

- Mileage: This is how mileage affects used spare parts

- Car recycling: What happens to the car when it is recycled?

- OEM original parts or aftermarket: these are the differences

- Advantages and disadvantages of new and used car parts

- Starting problems? Top 9 reasons why your car does not start

- What’s that smell from my car? Top causes and cures

- Advantages of shopping scrap car parts online vs. going to the local breaker yards...

- 10 most frequently purchased car parts from car breakers/junkyard

- Important car parts and their function

- Common car engine problems: Diagnosing, Troubleshooting and Fixes

- Best tips for setting up your own home car workshop

- 7 Car parts replacements and repair tasks you should not do yourself

- DIY Car Maintenance and Repair Tasks

- Guide: How to Maintain and Protect Your Car Engine

- Best practices for Engine Rebuild

- Common Causes of Rear Differential Noise, troubleshooting, and how fix it

- Common Causes of power steering noise and how fix it

- Your Guide to Car Engine Components and Functions

- Licence plate and VIN information

- Top 10 of the most popular brands in second-hand autoparts

- France is just so cool